Более чем 100-летний опыт технического прогресса позволил нам стать ведущим производителем в области частотных преобразователей, сервоприводов, систем управления и робототехники.

Picking | Packing

Примеры решений Applications Picking | Packing

Обзор

Picking and Packing / Unpacking and Packaging

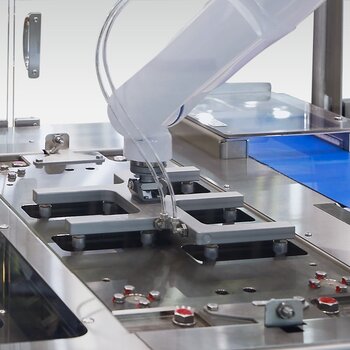

Picking and Packing is a variation of Pick & Place for Packaging applications, where the placing motion is modified to fill parts into containers, boxes or crates. Some people say PPP - Pick, Place and Pack. Therefore, it is a core process in Packaging Industry and Logistics. Compared to classical Pick&Place, the Placing motion of a packaging operation requires some more motion versatility to place or stack parts in a certain set-down pattern, this is why 6-axis GP Series robots are used here. When placing parts into Carton boxes, flexible trajectories could be required to prevent side walls or lid of cartons to fold in.

Depending on the gripper design, all kind of workpieces like boxes, bottles, bags can be packed.

Motoman Robots for Pick and Pack Applications

From Ice Cream, Chocolates, Sweets, bottles and bottle packs to industrial End-of-Line Packing - MOTOMAN Robots are a good choice for these jobs.

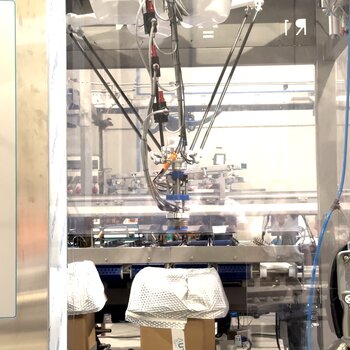

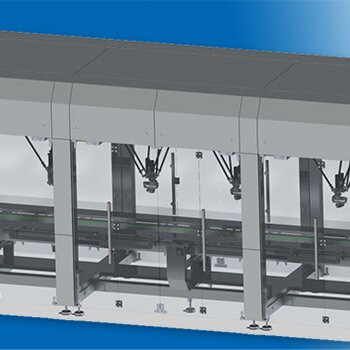

- Delta Robots (MPP Series) - Putting parts vertically into a box (High throughput solution)

- Scars-Robots (SG Series) - Putting parts vertically into a box (low-cost solution)

- Cobots (HC Series) - for smart fenceless stations with public traffic around

- 6-Axis-Robot (GP Series) - a balanced solution of high reliability, motion versatility and throughput

- Dual Arm Robots - for complicated, multi-step applications

Human-Robot Collaborative Packing with Motoman HC Series Cobots

With our hand-guided, easy-to-use collaborative HC Series robots, it is possible to create smart, fenceless entry level automatic Pick & Pack Stations.

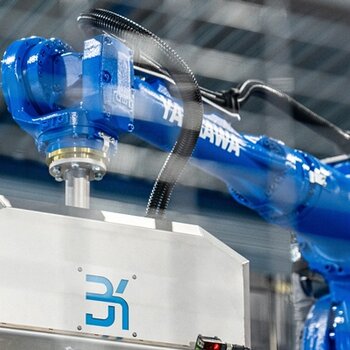

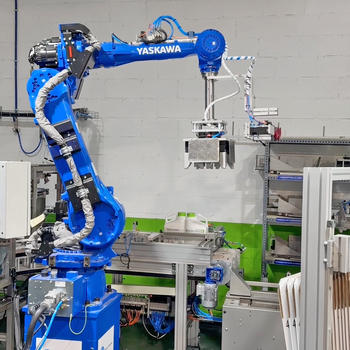

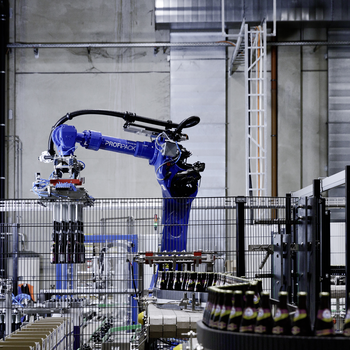

Picking & Packing with Motoman GP Series Robots

Pick & Pack application is typically integrated into a workflow of packaging lines. Those lines have housings and fences. Here, our GP-Series robots are the right choice for smooth integration, high versatility and high throughput.

Dual-Arm Robots for Pick and Pack Applications

Dual Arm robots (SDA Series) are the best choice for tricky packing - or unpacking applications, which are directly copied from manual workflows.

One Robot for all - Case Erection, Picking, Placing and Palletizing

The next video demonstrates how a single MOTOMAN robot from YASKAWA can be used to erect a box, pick up a food related product, pack it into a box, close the box and finally palletise the full box onto a pallet. This kind of robotic automaton brings advantages for low level output where various processes can be combined using just a single robot.

Unpacking with Motoman Robots

Unpacking is interesting for Logistics / Contract Packagers ("Copackers"), who are companies packaging products in tailored sizes for their clients. The packaging and labelling services can be used for many types of products including foods, pharmaceuticals, household products, and industrial products.

Unpacking is more challenging than picking - opening the carton and having the right gripper design and trajectory to take out parts safely.