Более чем 100-летний опыт технического прогресса позволил нам стать ведущим производителем в области частотных преобразователей, сервоприводов, систем управления и робототехники.

Long-term relationship with Visser Horti Systems

It is a company that believes in Europe and the European idea - and that for a company that was founded in Japan over a hundred years ago. And there's more Japanese about Yaskawa Electric: they focus on a long-term relationship with the customer. 'That means we have to be patient,' says Erik van Driel, director and business unit manager Drives, Motion and Control (DMC) of Yaskawa Benelux BV. 'And we are.'

The company has been around since 1915, has more than 14,500 employees worldwide and produces 2.2 million servo systems plus more than 2 million variable speed drives annually. Yaskawa Electric shows impressive figures. Van Driel. 'You will find our products in many control cabinets.'

Yaskawa: Japanese player with an increasingly solid base in Europe

Yaskawa Electric is one of the world market leaders in the field of industrial automation and with mechatronics as its focus. The company, with sixty offices worldwide, makes and sells drives, motion controls, robot systems, generators, converters and software. In the Benelux the company is located in Eindhoven and has a total of 28 employees. Yaskawa Benelux is led by Eddie Mennen and Van Driel, and operates in two business units: Robotics and Drives Motion & Control (DMC). In Eindhoven is also the Yaskawa Benelux Academy, with an extensive training program for beginners and advanced students within the company

Patents

'Yaskawa is an innovative company', says Van Driel with some pride. It has been represented in the Derwent Top 100 Global Innovators, an annual election by Japan's Clarivate Analytics, for six consecutive years. 'And there we are, among renowned and younger companies like Amazon, Uber and Microsoft. We owe the election to the number of patents we register each year, and the influence we have in the industry. Innovation to help our customers even better, that's what it's all about'.

Also special is Yaskawa's attitude towards Europe. The company now - quite deliberately - has nine factories on the continent; the latest was opened in Slovenia in 2019. The factories produce, among other things, 80 percent of all robotics for Europe, as well as 50 percent of all products of the DMC business unit.

There is a reason for that, says Van Driel. 'You could say that as a company we believe in Europe. One of the reasons is that we want to be close to the customer, also in terms of production. In our opinion, good service is closely related to physical proximity. If you have factories close to the customer, you can deliver faster and you know the local market better. And of course you can offer better service, because it is faster. Moreover, in this way we are taking our social responsibility seriously: no jobs or production in low-wage countries.'

Customer language

In a number of ways, Yaskawa is quite Japanese, says Van Driel. 'We value long term relationships for instance. And we have a lot of patience for that. That is really Japanese, yes. Investing first: getting to know the customer, understanding who he is. And then what he wants. What is his demand? And what is the question behind that question? Because that's what it's all about. The customer wants a servomotor. Of course you can deliver it. But what does that mean? Does he want to focus on faster production? Or does he want less downtime? You can only really help a customer if you know his real question. And you can only answer that question if you know the customer. When you know what drives them, what their needs are.'

According to Van Driel, this way of working is 'quite unique'. Of course, he says, at Yaskawa we also have to make a profit at the end of the line. 'At the same time, we work on our long-term strategy on a daily basis.'

Yaskawa - and that is another reason to produce in Europe - wants to speak the language of the customer, according to Van Driel. 'And we mean that literally and figuratively. Listening and probing. Our people are trained to do that. And we exchange those experiences internationally.'

Accuracy

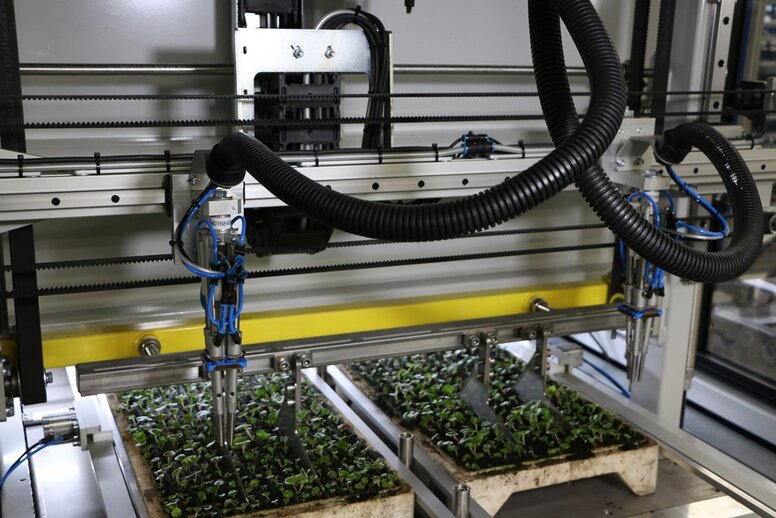

One of Yaskawa's customers is Visser Horti Systems in 's-Gravendeel. The company has been designing and manufacturing machines and production lines for the horticultural sector since 1967. The relationship with Yaskawa goes back about ten years, says technical manager Jacko van de Ree. 'We were having problems with a number of parts of our transplanting machines. After a lot of research, the Purchasing Department eventually found Yaskawa. Together with Yaskawa's engineers we were able to develop and produce good new machines.'

If you know each other longer, you can think along with each other'.

With transplanters, where plants are transferred from a tray to a larger tray, it's about two things: capacity and accuracy, says Van de Ree. 'And they've helped us with that.' So well, in fact, that in the years to follow Yaskawa was allowed to supply parts for many different machines owned by Visser. The quality of the parts is beyond discussion. The communication lines between the two companies are short.

Van de Ree also recognizes Yaskawa's long-term approach. 'We're a family business, we're all about the long term. And that's where we find each other. It's also practical: our machines have a lifespan of ten to fifteen years, so you don't want to keep working with new suppliers. Our customers don't like that. If you know each other longer, you can - as we do - think together and help each other.'

Innovative character

Erik van Driel on the innovative character of Yaskawa: 'This is aimed at reducing the integration time and project risks for our customers. Singular Control is a great example of this. This is a control platform that is used to control the servo axes in the robots and the external axes, servo systems or frequency inverters. With Singular Control we offer one platform to easily integrate all motion in the application.'

Another example of innovation is i3 Mechatronics. 'This concept is our response to the developments surrounding smart industry. We now know that no two issues are the same in this area. Therefore, a flexible concept that allows us to deliver customised solutions is important. Yaskawa's servo systems and frequency inverters already receive a lot of process data for their own control algorithms. With i3 Mechatronics we can unlock that data for our customers and convert it into valuable information.'

This article appeared inLink Magazine August 2021